Terry Jackson

In 1914 the German Army went to war with the traditional spiked helmet made of leather. As with the other belligerents, the rapid increase in artillery firepower meant that something more resistant to shrapnel and flying debris was needed.

The first attempt to give some protection was by the Army Group Gaede* in early 1915. (*The unit’s commander). They were active in the Vosges. It is a very rocky area and many of the trenches were in rock cuttings. This led to a high level of splintering from shell explosions with the inevitable effect of wounding, especially to the head.

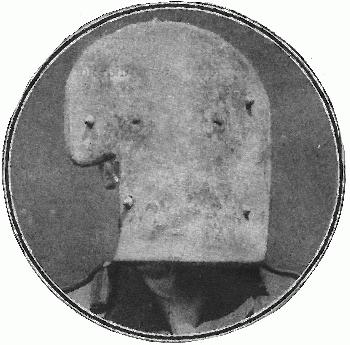

With no immediate developments at the national level, the group decided to design one themselves. Lt-Colonel Hesse the Chief of Staff headed the project. This was a specialised skull cap somewhat more developed than the French calotte and included a nose-guard. It was quite heavy and a small cloth and leather cap was worn underneath for comfort. The steel was 5-7mm thick and weighed 2.05kg. Most were subsequently melted down and are rare nowadays. (Photo right: Gaede helmet: see end of article for other helmets).

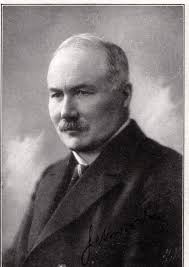

At a more national level, in 1915 Professor Friedrich Schwerd of Hannover Technical Institute and also a Captain in the Landwehr, was in contact with Professor August Bier, the Naval Doctor-General and an army consultant. Schwerd had set up an electromagnet with which he intended to extract splinters from the brains of injured soldiers. During their conversation Schwerd assured Bier that a helmet could be produced to protect against splinters and shrapnel, but not bullets, A study of 100 head wounds showed only 20% were from bullets, the remainder being from shell fragments or shrapnel. A very small splinter could cause massive brain damage and most head wounds were sufficiently severe to take the soldier out of army service. Bier sent this information to 2nd Army. Both experts were of the opinion that a protective helmet could and should be developed. (Photo right: Professor Schwerd)

Copies were sent to the various Army doctors and von Falkenhayn then Chief of General Staff. He in turn advised the Prussian War Ministry that this should be acted upon. After high level discussions in August the War Ministry informed informed Krupp Essen that the Juncker Foundry in Berlin would develop the helmet and Krupp were to provide the steel.(Junker had already been experimenting with steel helmet designs). By September 1915 after taking expert advice Schwerd reported to the Clothing Section of the War Ministry that a helmet should be produced.

The helmet was to be of 0.5mm thick steel with neck and forehead protection. 5% nickel steel was preferred, but 11% manganese steel could be used. It would be able to protect against shrapnel and small splinters but not bullets. Two side vent lugs would allow ventilation. Anti-rusting paint and a top coat would be applied. Consideration was then given to design based on the statistics-. 80% of head wounds were from artillery fragments/shrapnel and only 20% from rifle fire.

By September 1915 Schwerd had determined what rationale was required for the production of a helmet and had discussed the matter with several specialist companies. It would be designed to give protection against shrapnel and splinters. Protection against rifle bullet penetration was not feasible as the weight of the extra protection would make the helmet too heavy to be worn. Splinter fragments would threaten from any angle. The helmet also had to allow for soldiers firing whilst lying down. Thus the characteristic shape of a bowl with a peak, a dip by the ears and neck protection produced its recognisable shape, which was similar to knight’s helmets of the past. The helmet would have two proud lug holes to the sides for ventilation and a liner with three pads and a chin strap attached to the internal part of the lugs. After much discussion a separate metal forehead shield was developed which could be strapped from the side lugs. In theory this would assist snipers as they would be firing from a fixed spot and muzzle flash might reveal their position. It proved to be unpopular and was not extensively used.

Various factories were employed in the trials and manufacture of the helmet and liner, reflecting Germany’s abundance of specialist engineering and military equipment companies.

Eventually after many reviews, it was aimed to produce a one piece helmet of 5% nickel steel or 11% manganese steel. After considerable testing, the first shipment of helmets for field study was sent to Captain Rohr’s 1st Assault Battalion in December 1915. These proved satisfactory and by February 1916 they were being used at Verdun. Following good field results, von Falkenhayn authorised a general issue in the same month. The Allies soon became aware of this development and the Parisian newspaper ‘Le Temps’ carried an article on the helmet on 10 March 1916. Gradually more units were issued with the helmet. Austria purchased 416,000 in late 1916 and began producing its own model in May 1917 and manufactured 534,000 themselves. Minor adjustments such as the toning down of light reflection and liner improvements were made over time. (Photo right: Willy Rohr).

In September 1916, through its Military Attaché in Washington DC the Americans attempted to purchase a specimen, but the Prussian War Ministry were unable to oblige. However, one was eventually given to the Americans via Paris.

Turkey also ordered helmets from Germany in 1918. The front visor was removed and the sides trimmed. It was suggested that was to enable the soldier to touch his head on the ground during prayer, but it was to give better ventilation. Only 5400 were delivered. (Photo right: helmet with visor)

In 1918 a variation was introduced with cut outs at the side. This has often been identified for use by wireless operators to accommodate headsets. However, it was to give better ventilation and only limited numbers were issued. As Germany struggled towards the end of the war, recycling of used or damaged helmets was common due to the shortage of material caused by the Allied blockade. It has been estimated that about a million helmets were produced during the First World War

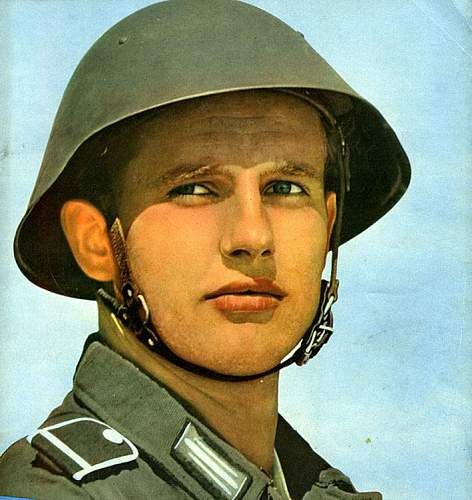

After the War various organisations wore the helmet during the internal struggles in Germany. Prior to the Second World War the helmet was redesigned. It retained the traditional shape but with a shallower bowl of thicker metal. The external lugs were removed, the side air vent being flush. Various internal organisations (Fire/Police etc) had adapted designs. German paratroopers were issued with a brimless helmet.

Towards the end of the Second World War a new design was being tested. Although similar to the original it had no turned curves which were a structural stress weakness. It was the helmet adopted by the East German Authorities until re-unification. Like most other nations Germany is now using a composite material helmet.

(For further information see ‘The History of the German Steel Helmet 1916-1945 by Ludwig Baer-ISBN 0-912138-31-9. Several other books are available that cover helmets and body protection).

Cut-out helmet

Cut-out helmet

Body armour

Current German Helmet

East German Helmet

Sniper shield

Square-dip Helmet

Visorless Helmet